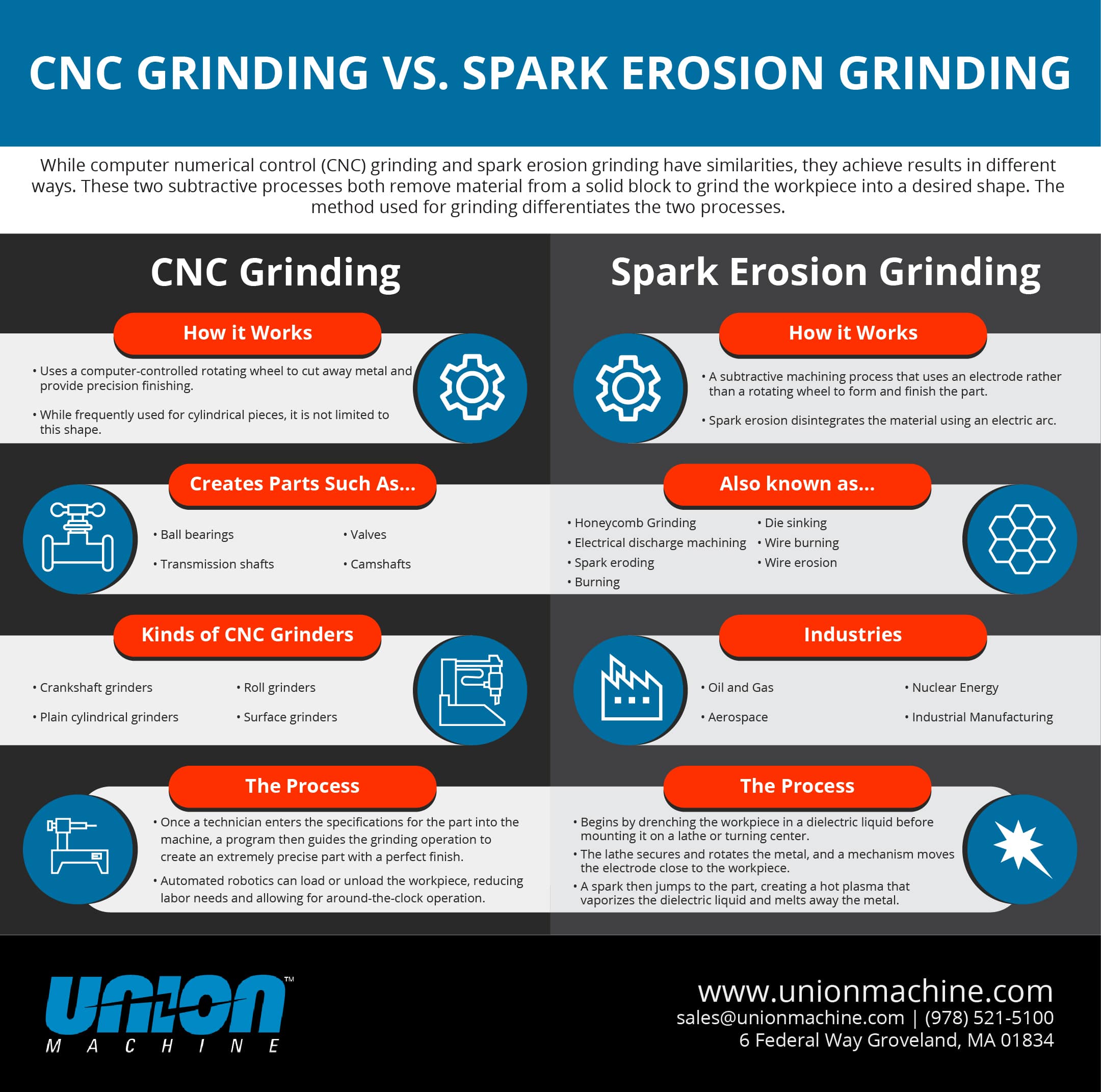

While computer numerical control (CNC) grinding and spark erosion grinding have similarities, they achieve results in different ways. These two subtractive processes both remove material from a solid block to grind the workpiece into a desired shape. The method used for grinding differentiates the two processes.

What is CNC Grinding?

CNC grinding uses a computer-controlled rotating wheel to cut away metal and provide precision finishing. While frequently used for cylindrical pieces, it is not limited to this shape. The CNC machining process is popular for creating ball bearings, transmission shafts, valves, camshafts, and other components that require adherence to strict tolerances and flawless finishes.

CNC grinding uses a computer-controlled rotating wheel to cut away metal and provide precision finishing. While frequently used for cylindrical pieces, it is not limited to this shape. The CNC machining process is popular for creating ball bearings, transmission shafts, valves, camshafts, and other components that require adherence to strict tolerances and flawless finishes.

There are multiple types of CNC grinders, including:

- Crankshaft grinders

- Plain cylindrical grinders

- Roll grinders

- Surface grinders

Computer numerical control mitigates the risk of human error. Once a technician enters the specifications for the part into the machine, a program then guides the grinding operation to create an extremely precise part with a perfect finish. Automated robotics can load or unload the workpiece, reducing labor needs and allowing for around-the-clock operation.

These unmanned operations require only intermittent observation to ensure that the machine is working correctly. Reducing the need for manual intervention increases precision, worker safety, and cycle time during the manufacturing process.

What is Spark Erosion Grinding?

Spark erosion grinding may be referred to by various names, such as:

- Electrical discharge machining (EDM)

- Spark eroding

- Burning

- Die sinking

- Wire burning

- Wire erosion

When hard metals need to be shaped into intricately shaped pieces, electrical discharge machining is often the best process. Many industries use spark erosion grinding, including oil and gas, aerospace, nuclear energy, and industrial manufacturing. EDM creates a shape without touching the metal, making it useful for machining delicate workpieces.

The process begins by drenching the workpiece in a dielectric liquid before mounting it on a lathe or turning center. The lathe secures and rotates the metal, and a hydraulic or electronic mechanism moves the electrode close to the workpiece. As it gets close enough, a spark from the electrical discharge jumps to the part, creating a hot plasma that vaporizes the dielectric liquid and melts away the metal in a very controlled and precise manner.

Spark Erosion Grinding Services from Union Machine

Click to Enlarge

Traditional CNC grinding is a valuable tool for machining precision parts with a high-quality, flawless finish. For hard and electrically conductive metals, however, spark erosion grinding can provide precise and intricate details.

At Union Machine, we can help you determine the best machining process for your application. Our company is an original equipment manufacturer and prime contractor for the aerospace industry. For over 60 years, we have been providing jet engine components and other precision parts from our AS9100D- and ISO:2015-certified facility. We offer cost-effective, burr-free grinding with a variety of alloys, metals, and engineered plastics.

To learn more about how we can help you with your machining needs, contact us today.