Union Machine is a Service-Disabled Veteran-Owned family business that has served clients for more than 60 years. We are an OEM provider of primarily jet engine components and other precision-made parts. Our services include:

- CNC Turning

- CNC Milling

- Airflow Testing

- Laser Cutting

- Laser Drilling

- Spark Erosion Grinding (Honeycomb Grinding)

CNC Turning

Our CNC turning capability is at the core of our organization. We have decades of experience turning high temperature alloys with high precision. Our jet engine machining portfolio includes seals, actuating rings, nozzles, shrouds, cases and combustors up to 38″ diameter.

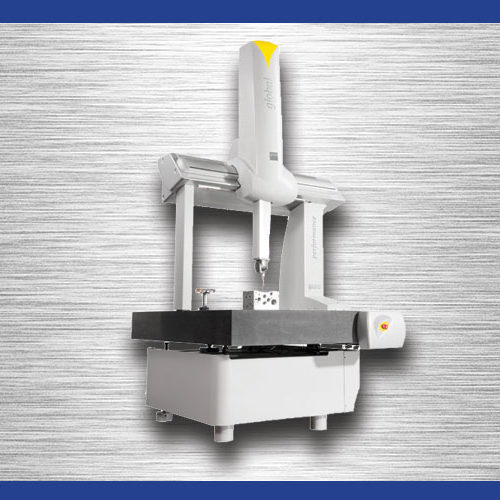

CNC Milling (5-Axis)

Our experienced CNC milling department can handle a wide range of applications including 5 axis milling and contour milling. We have experience holding tight tolerances and true positions of as small as 0.001″ and have the capability to probe tight tolerance parts like gearboxes on the machine.

Contour Machining

Our contour machining services produce continuous curves in the material. Many industrial applications that require ultra-precise components benefit from contour machining since it creates very intricate parts when necessary.

Contour Machining (4/5 Axis) Equipment

- (1) Mori Seiki MV 65/60 (48x24x32)

- (1) Mori Seiki MV 45/40 (30x17x20)

- (3) Matsuura MC-780-VDC (29x16x19)

- (1) Matsuura MC-800-VDC (48x16x20)

- (3) Matsuura MC-600H (23x18x19)

- (1) HMC 410 (12x18x18)

- (1) Excel 810 (28x15x18)

- (1) Mori NH5000 (40x20x27)

Automated Airflow Testing

Airflow Testing

Airflow testing is the measurement of the movement of air through a specific product or component,

Usually tested for an air moving device such as a blower or fan. Airflow testing is also an absolute must for new turbine engine blades, shroud, manifold, combustors, nozzles, and more.

Union Machine is capable of building a fixture customized to your specifications in a short period of time and in a cost-efficient manner.

Laser Cutting

Laser cutting allows manufacturers to cut into various materials and create patterns and designs. It’s ideal for applications that require specialized or intricate parts since it does not require custom-designed tools like other fabrication methods. Our 5-axis laser cutters cover a wide array of applications and geometries up to 40″x20″x30″.

Laser Drilling

Laser Drilling

Laser drilling is the process of creating holes in a material with a fiber laser beam. The holes may be thru-holes or small dents to roughen material and prepare it for coating. Manufacturers have total control over the laser drill’s intensity, heat, and duration, and can create a variety of holes and impressions on a part. Our laser on the fly-technology also allows us to generate airflow holes in combustion liners with minimal heat distortion.

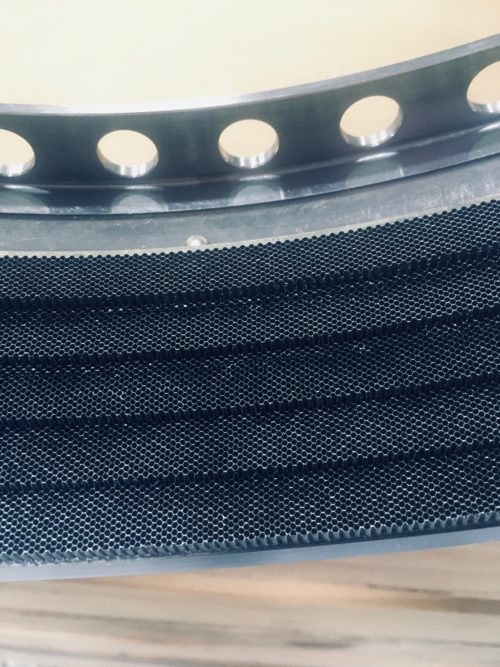

Spark Erosion Grinding (Honeycomb Grinding)

Spark erosion grinding systems remove metal stock using AC current. The process relies on EDM technology, which allows manufacturers

to arc-grind profiles onto metal parts. Aerospace and other professionals often opt to repair and reshape parts using spark erosion grinding rather than replacing expensive, specialized components. Honeycomb grinding creates a burr-free, honeycomb finish as well as minimal cutting force strain on parts.

Contact Union Machine Today

At Union Machine, we leverage our industry expertise to offer leading machining services to our clients. With 60 years of aerospace specialization, we know how to tackle even the most complex part or challenging deadline. We offer state-of-the-art modeling and programming software, enterprise resource planning, and secondary services such as plating, welding, heat treatment, and more. Contact us today to see what we can do for you.

Check out our Brochures and equipment list for additional capability details.