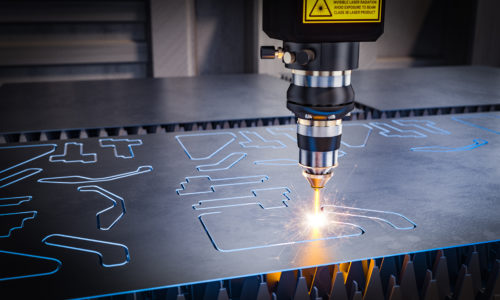

While 3-axis laser cutting has become relatively common in recent years, advances in laser cutting equipment have led to the development of 5-axis laser cutters. This is the preferred process for 3D laser cutting, as it enables the rapid, easily repeatable manufacture of complex components by cutting along these five axes:

X-axis (left to right)

X-axis (left to right)- Y-axis (forward and backward)

- Z-axis (up and down)

- A-axis (rotational)

- B-axis (tilted)

The addition of the A and B axes makes it possible to machine parts from virtually any angle with a greater level of precision. Common items machined with 5-axis laser cutting include:

- Blades

- Wheels

- Curved, circular, or cylindrical parts

- Parts requiring angular cuts

5 Axis Laser Cutting vs. 3 Axis Laser Cutting

Additionally, a limited number of axes makes it challenging to machine complex three-dimensional parts. Instead, 3-axis laser cutting is a more suitable choice for smaller, simpler components. 5-axis laser cutting enables the rotation and tilt of the table, making it possible to produce complex parts efficiently and accurately. For larger three-dimensional parts or complex designs, 5-axis laser cutting is the optimal choice.

The Benefits of 5-Axis Laser Cutting

Single Setup

In contrast to 3-axis laser cutting, 5-axis laser cutting will often require a single setup. This allows for the efficient and accurate machining of complex parts, greatly improving efficiency and reducing the number of potential mistakes.

Angular Holes

5-axis machining also has an advantage when it comes to drilling angular holes. While 3-axis laser cutting requires multiple setups for every hole, the tilting and rotating abilities of 5-axis laser cutting make it possible to drill multiple holes from different angles without ever removing the component. This increases accuracy and makes for a more timely production process.

Complex Parts

Each of these benefits contributes to what is perhaps the biggest strength of 5-axis laser cutting: the ability to efficiently machine complex, high-quality parts. This process is easily repeatable. After the machine has been programmed once, no more effort is required to create an identical run of components.

How 3D Laser Cutting Works

The 3D laser cutting process focuses a highly coherent beam of light on the workpiece. In order to shape the part to the desired specifications, the laser will melt, burn, or vaporize the unwanted material. As laser cutting only impacts a small portion of the material, it is able to create parts with minimal warping.

5-Axis Laser Cutting at Union Machine

At Union Machine, we are AS9100D, NADCAP, and ISO 9001:2015 certified, and our skilled team is standing by to assist with your next project. For more information regarding how Union Machine can help with your 5-axis laser cutting needs, feel free to contact us today!