Laser drilling uses thermal energy from laser lights to create holes and impressions of any size into a variety of materials. Union Machine offers various types of laser drilling processes, including single-shot laser drilling, trepan laser drilling, helical laser drilling, percussion laser drilling and laser drilling on-the- fly. Laser drilling offers many advantages over conventional forms of drilling and has evolved into a highly efficient process capable of producing exceptional results.

Laser Drilling Benefits and Advantages

Laser drilling is a popular solution for many manufacturing processes because it is a high-speed process that consistently and accurately creates precise dimensions, sizes, and positioned holes. Laser hole drilling processes are capable of efficiently producing holes with aspect ratios of 30:1 and higher, even through shallow approach angles.

Our 5-Axis laser drilling process provides the capability to drill holes at compound angles for directed airflow. We also provide laser drilling on-the-fly services, allowing the part to cool between each shot and reducing the amount of heart and potential for distortion in the workpiece.

Since the laser drilling process uses a beam of light, it is a non-contact process that isn’t affected by the mechanical wear of a drill bit. Tough materials can be drilled through without disrupting the coating or bond. Laser drilling can be used with a variety of materials, including plastic, rubber, wood, ceramic, metals, and diamonds.

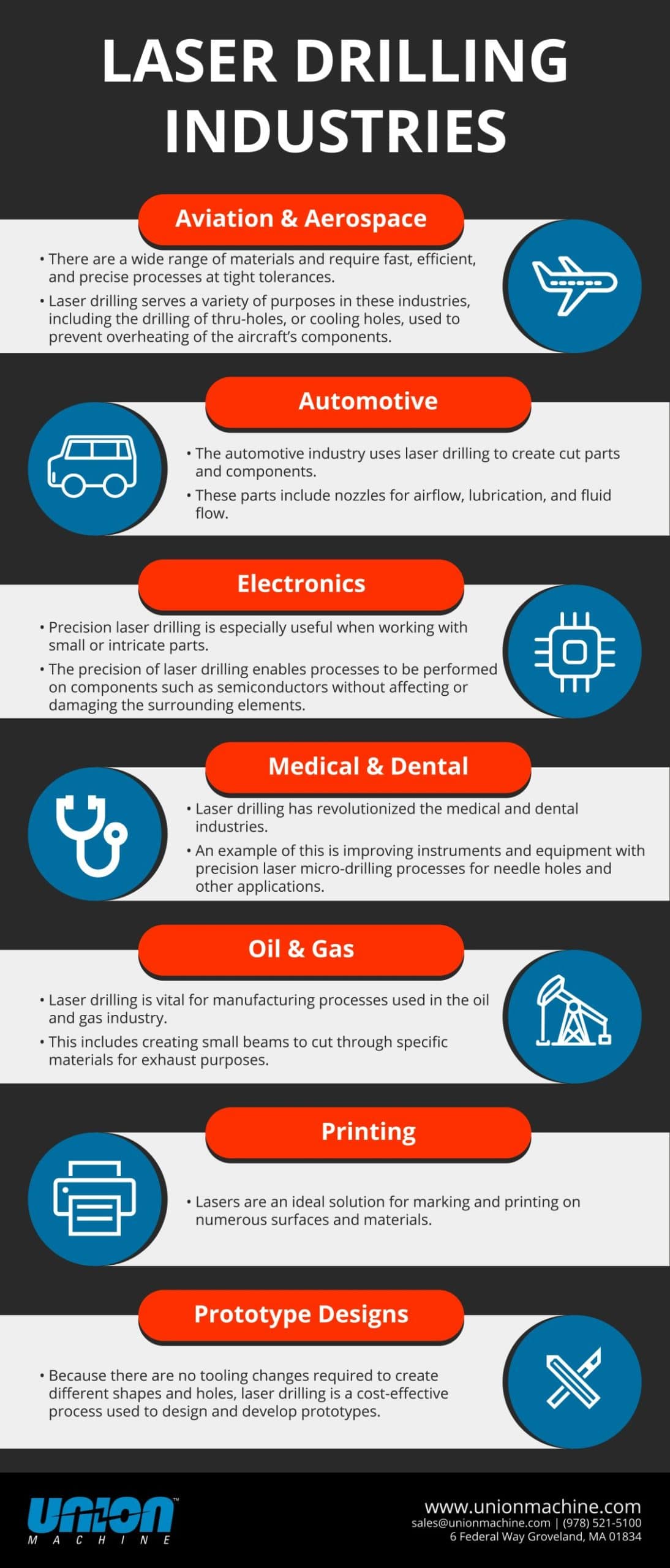

Laser Drilling Industries & Applications

Laser drilling is useful in a broad range of industries, including:

- Aviation and Aerospace. The aviation and aerospace industries use a wide range of materials and require fast, efficient, and precise processes at tight tolerances. Laser drilling serves a variety of purposes in these industries, including the drilling of thru-holes, or cooling holes, used to prevent overheating of the aircraft’s components.

- Automotive. The automotive industry uses laser drilling to create cut parts and components such as nozzles for airflow, lubrication, and fluid flow.

- Electronics. Precision laser drilling is especially useful when working with small or intricate parts. The precision of laser drilling enables processes to be performed on components such as semiconductors without affecting or damaging the surrounding elements.

- Medical and Dental. Laser drilling has revolutionized the medical and dental industries by improving instruments and equipment with precision laser micro-drilling processes for needle holes and other applications.

- Oil and Gas. Laser drilling is vital for manufacturing processes used in the oil and gas industry, including creating small beams to cut through specific materials for exhaust purposes.

- Printing. Lasers are an ideal solution for marking and printing on numerous surfaces and materials.

- Prototype Designs. Because there are no tooling changes required to create different shapes and holes, laser drilling is a cost-effective process used to design and develop prototypes.

Laser drilling is one of the most commonly used manufacturing processes in the world, used for a variety of applications including:

- Creating thru-holes for air cooling vents

- Creating small dents in material to prepare it for coating or gluing purposes

- Drilling micro holes and precision holes

- Ceramic drilling

- Silicon drilling

- Laser drilling to cut through rock

- Enhancing diamonds

For more precise applications & projects, Union Machine also offers spark erosion grinding services as well. Visit our Spark Erosion service page today for more information.

Custom Laser Drilling from Union Machine

At Union Machine, we strive to provide exceptional customer service and the highest quality processes possible. Our state-of-the-art facility and highly skilled team are capable of delivering precision laser drilling services for any application. To request a quote or learn more about our laser drilling capabilities, contact us today.